Have you ever encountered the frustrating problem of a stripped screw hole in wood? It can be a common issue, especially when dealing with furniture or other wooden objects that undergo constant use or assembly. But fear not, as there are effective solutions to fix this problem and restore the integrity of the screw hole. In this guide, we will explore various techniques and tools that will help you tackle stripped screw holes in wood with confidence and precision.

Whether you’re a DIY enthusiast or a professional woodworker, understanding how to fix stripped screw holes is an essential skill to have in your toolkit. Not only can it save you time and money, but it also allows you to salvage and preserve your wooden projects, ensuring their longevity and stability. From simple methods like using toothpicks or wooden dowels to more advanced techniques such as using epoxy or oversized screws, we will delve into the step-by-step process of repairing stripped screw holes. So, let’s roll up our sleeves and get ready to conquer this common woodworking dilemma!

How to fix stripped screw holes in wood:

- Remove the screw from the hole.

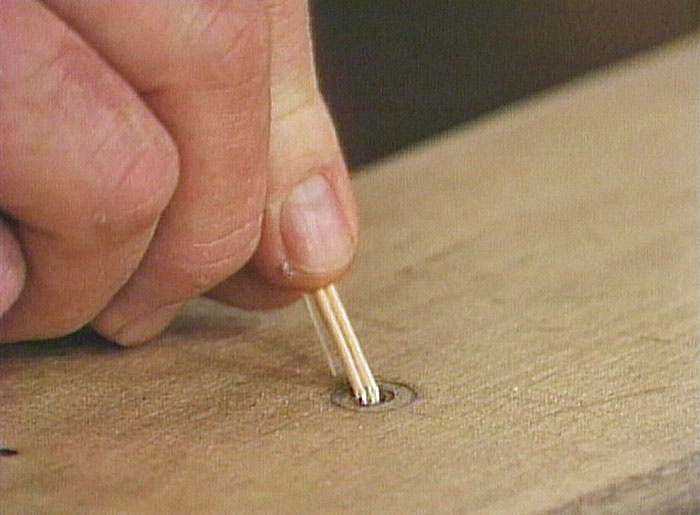

- Fill the hole with wooden toothpicks or matchsticks coated in wood glue.

- Allow the glue to dry completely.

:max_bytes(150000):strip_icc()/how-to-fix-a-stripped-screw-hole-3536468-FINAL-5b982891c9e77c005037660c.png)

How to Fix Stripped Screw Holes in Wood

Stripped screw holes in wood can be frustrating and pose a challenge when trying to secure objects. However, with the right tools and techniques, you can easily fix stripped screw holes and ensure a secure and durable connection. This step-by-step guide will walk you through the process of fixing stripped screw holes in wood, allowing you to complete your project successfully.

Step 1: Remove the Stripped Screw

Before you can fix a stripped screw hole, you need to remove the stripped screw itself. Start by using a screwdriver or a screw extractor tool specifically designed for this purpose. Insert the tool into the stripped screw head and turn it counterclockwise to loosen and remove the screw. If the screw is still stuck, you can try using pliers to grip the screw head and twist it out.

Step 2: Fill the Hole with Wood Filler

Once the stripped screw has been removed, you can proceed to fill the hole with wood filler. Choose a wood filler that matches the color of your wood for a seamless finish. Using a putty knife or a similar tool, apply the wood filler to the stripped screw hole. Make sure to overfill the hole slightly to account for any shrinkage that may occur as the filler dries. Smooth out the surface of the wood filler and let it dry according to the manufacturer’s instructions.

Step 3: Drill a Pilot Hole

After the wood filler has dried, you need to drill a pilot hole to create a new starting point for the screw. Select a drill bit that is slightly smaller than the diameter of the screw you will be using. Place the drill bit into a drill and position it over the filled hole. Start drilling slowly, applying gentle pressure. Once the pilot hole is drilled, remove any wood debris from the hole.

Step 4: Insert the New Screw

With the pilot hole in place, you can now insert the new screw into the stripped screw hole. Choose a screw that is slightly longer than the original one to ensure a secure connection. Align the screw with the pilot hole and use a screwdriver or a drill to drive it into the wood. Be careful not to overtighten the screw, as this can cause the wood to split. Stop turning the screw once it is snugly in place.

Step 5: Finishing Touches

After successfully fixing the stripped screw hole, take a moment to inspect the area for any imperfections. If necessary, you can use sandpaper or a wood file to smooth out the surface and create a seamless finish. Additionally, you may consider applying a wood stain or paint to match the surrounding wood, further enhancing the appearance of the repaired area.

Step 6: Reinforce with Wood Glue (Optional)

If you want to add extra strength and durability to the repaired screw hole, you can reinforce it with wood glue. Apply a small amount of wood glue to the walls of the hole before inserting the screw. This will help create a tighter bond between the screw and the wood, reducing the likelihood of future stripping. Allow the glue to dry completely before using the screw.

Step 7: Repeat if Necessary

If you encounter multiple stripped screw holes in the same piece of wood, repeat the above steps for each hole. Remember to remove the stripped screw, fill the hole with wood filler, drill a pilot hole, and insert a new screw. Take your time and ensure each repair is done correctly to achieve the desired results.

Step 8: Seek Professional Help if Needed

If you are unsure about your ability to fix stripped screw holes in wood or if the damage is extensive, it is always best to seek professional help. A professional carpenter or handyman will have the necessary expertise and tools to handle the repair effectively and ensure a long-lasting solution.

Step 9: Prevent Future Stripped Screw Holes

To prevent future stripped screw holes in wood, it is important to use the correct size and type of screw for the job. Avoid overtightening screws and be mindful of the wood’s condition. If you notice any signs of weakening or stripping, take immediate action to address the issue before it worsens. Additionally, consider using lubricants or wax coatings on screws to reduce friction during installation.

Step 10: Regular Maintenance and Inspection

Lastly, to ensure the longevity of your wood projects, it is essential to perform regular maintenance and inspection. Check screws periodically for any signs of loosening or stripping and make any necessary repairs promptly. By staying proactive, you can prevent future stripped screw holes and maintain the integrity of your woodwork.

Frequently Asked Questions

Here are some commonly asked questions about how to fix stripped screw holes in wood:

Q: What causes screw holes to become stripped in wood?

A: Screw holes in wood can become stripped due to various reasons. One common cause is over-tightening of the screw, which can lead to the threads of the wood being damaged and the hole becoming larger than the screw. Another cause can be using the wrong size or type of screw for the wood, causing the threads to not properly grip the wood and resulting in stripping.

Q: How can I fix a stripped screw hole in wood?

Q: How can I fix a stripped screw hole in wood?

A: There are a few methods you can try to fix a stripped screw hole in wood. One option is to use wooden toothpicks or matchsticks. Simply dip them in wood glue and insert them into the stripped hole, then break off the excess and let the glue dry. Another method is to use wooden dowels. Drill out the stripped hole slightly larger, apply wood glue to a wooden dowel, and insert it into the hole. Once the glue is dry, you can cut off the excess dowel and re-insert the screw.

If the stripped hole is too large for toothpicks or dowels, you can try using a wood filler or epoxy. Fill the hole with the filler or epoxy, let it dry and harden, and then re-drill the hole and insert the screw.

Q: Are there any specialized tools available for fixing stripped screw holes in wood?

A: Yes, there are specialized tools available for fixing stripped screw holes in wood. One such tool is a screw hole repair kit. These kits usually include various sizes of wooden dowels, drill bits, and wood glue. They provide a convenient solution for repairing stripped screw holes in wood without the need for additional tools or materials.

Another specialized tool is a screw extractor. This tool is designed to remove stripped screws from wood by drilling a hole into the screw and then using reverse threading to grip and remove it. However, it is important to note that screw extractors are typically used for removing screws rather than fixing stripped screw holes.

Q: Is it possible to prevent screw holes from becoming stripped in the first place?

A: Yes, there are some steps you can take to prevent screw holes from becoming stripped in wood. One important step is to choose the right size and type of screw for the wood you are working with. Using a screw with a proper diameter and thread pitch will ensure a secure and tight fit in the wood.

Additionally, it is important to avoid over-tightening the screws. Once the screw is snug and flush with the wood surface, stop tightening to prevent damaging the threads. Pre-drilling pilot holes can also help prevent stripping, especially when working with hardwood or dense woods. The pilot hole should be slightly smaller than the screw diameter to ensure a secure and strong connection.

Q: Can I use alternative methods to fix stripped screw holes in wood?

A: Yes, there are alternative methods you can try to fix stripped screw holes in wood. One option is to use metal inserts or threaded inserts. These inserts are typically made of brass or stainless steel and can be screwed into the stripped hole. The screw can then be inserted into the insert, providing a new and secure grip.

Another alternative method is to use a combination of wood glue and sawdust. Mix the wood glue with sawdust to create a paste-like consistency and apply it to the stripped hole. Let it dry and harden before re-inserting the screw. This method can provide a strong and durable fix for smaller stripped holes.

Remember, prevention is always better than a cure. Take preventative measures such as using lubricants, pre-drilling pilot holes, or using screws specifically designed for wood to avoid encountering stripped screw holes in the first place. However, if you do find yourself facing this problem, don’t panic. With patience, the right tools, and the knowledge gained from this guide, you can easily restore the integrity of your wooden surfaces and ensure secure and stable screw fittings. So, roll up your sleeves, put on your DIY hat, and confidently tackle those stripped screw holes with the skills you’ve acquired.

- How to Make Wood Look Weathered - May 14, 2024

- How to Solve Wooden Egg Puzzle - May 14, 2024

- How to Decoupage on Wood With Pva Glue - May 14, 2024